DuPro+ HSR

Cement for Extreme Environments

An environmentally friendly construction material with moderate heat of hydration and resistance to sulfuric acid and chloride penetration. As an alternative to special type portland cement products that are easy to work with and durable.

-

APPLICATIONS

APPLICATIONS

-

- Bridges

- Ports and Marine Construction

- Oil and gas

- Refineries and Smelters

- Energy Generation

- Water and Waste Treatment Facilities

-

-

PACKAGING

PACKAGING

-

- Jumbo Bag

- Bulk

- Sack 50 kg

-

-

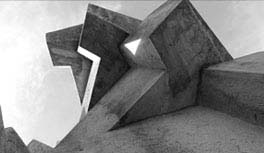

USER PROJECTS

USER PROJECTS

-

- RDMP Pertamina Balikpapan

- PLTU Karangkandri

- PLTU Pacitan

- PLTGU Tenayan Riau

- Kalibaru Jetty

- Youtefa Bridge

- PLTU Suralaya

- PLTU Pelabuhan Ratu

- PLTU Adipala Cilacap

- PLTU Indramayu

- Kalibaru Jetty, Jakarta

- PLTGU M Indramayu

- Pelabuhan Ratu

- PLTU Paiton

- PLTU Lontar

- PLTU Tanjung Awar-Awar

- Pertamina Cilacap

- Tanjung Emas Pier, Semarang

- PLTU Labuhan Banten

-

-

ADVANTAGES

ADVANTAGES

-

- High Sulfuric Acid Resistance

- Medium Chloride Resistance

- Better Concrete Permeability

- Higher Initial and Final Compressive Strength and Durability

-

-

STANDARD REFERENCE

STANDARD REFERENCE

- SNI 2049-2015 Tipe V

TYPICAL ANALYSIS DUPRO+ HSR (PORTLAND CEMENT TYPE V)

| QUALITY PARAMETER | UNIT | SNI 2049:2015 TIPE V |

TYPICAL PRODUCTS | VALUE RANGE | |

|---|---|---|---|---|---|

| Physical Properties: | |||||

| Compressive Strength: | |||||

| - 3 Days | Min | kg/cm2 | 80 | 230 | ±15 |

| - 7 Days | Min | kg/cm2 | 150 | 200 | ±15 |

| - 28 Days | Min | kg/cm2 | 180 | 320 | ±20 |

| - Fineness | Min | m2/kg | 180 | 320 | ±20 |

| - Air Content | Max | % | 12 | 4 | ±1.5 |

| Bonding Time: | |||||

| - Initial Binding Time (Vicat) | Min | Minutes | 45 | 175 | ±15 |

| - Final Binding Time (Vicat) | Max | Minutes | 375 | 305 | ±15 |

| - Final Penetration Apparent Binding (Vicat) | Min | % | 50 | 80 | ±10 |

| - Expansion due to sulfate Max | Max | % | 0.04 | 0.02 | ±0.01 |

| - Immutability of shape by autoclave | Max | % | 0.8 | 0.01 | ±0.02 |

| Chemical Properties: | |||||

| Magnesium Oxide (MgO) | Max | % | 6 | 1.4 | ±0.3 |

| Sulfur Trioxide (SO3) | Max | % | 2.3 | 2.0 | ±0.3 |

| Total Alkalies | Max | % | 3 | 2.0 | ±0.3 |

| Incandescent (LOi) | Max | % | 3 | 2.0 | ±0.3 |

| Insoluble Part | Max | % | 1.5 | 0.5 | ±0.1 |

| Tricalcium Aluminate (c3A) | Max | % | 5 | 2.6 | ±1.4 |

| Tetracalcium Alumino Ferrite (C4AF) + 2(C3A) | Max | % | 25 | 18.7 | ±2.5 |

Tanjung Emas Pier, Semarang

PLTU Indramayu, West Java

PLTU Suralaya, Cilegon, Banten