PwrPro

Extra Strong Cement

Cement with a high initial compressive strength that is environmentally friendly, optimizes the time it takes for the cement to harden and improves workability. Can be used for various buildings and infrastructure and has been certified green label.

-

ECO-FRIENDLY

ECO-FRIENDLY

- 29% reduction in CO₂ emissions compared to OPC cement

-

STANDARD REFERENCE

STANDARD REFERENCE

- SNI 8912 : 2020

(Hydraulic Cement, High Early type)

- SNI 8912 : 2020

-

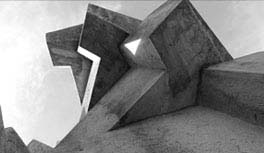

USER PROJECTS

USER PROJECTS

-

- Purwosari Flyover, Surakarta - Central Java

- Batang Industrial Estate, Batang - Central Java.

- Thamrin Nine Tower, Jakarta.

- Sabo Dam Merapi, Magelang - Central Java

- Salatiga Toll Road, Salatiga - Central Java

-

-

ADVANTAGES

ADVANTAGES

-

- High quality performance

- More economical

- Environmentally friendly

-

-

APPLICATIONS

APPLICATIONS

- Readymix concrete, & Precast medium - high quality

-

PACKAGING

PACKAGING

-

- Jumbo Bag

- Bulk

-

-

TKDN VALUE

TKDN VALUE

- 96,99%

TYPICAL ANALYSIS OF PWRPRO (HYDRAULIS CEMENT TYPE HE)

| QUALITY PARAMETERS | UNIT | SNI 8912:2020 TIPE HE |

PRODUCT TYPICAL | VALUE RANGE | |

|---|---|---|---|---|---|

| - Fineness | Min | m²/kg | - | 400 | ±30 |

| - Length Change with Autoclave | - | % | - | 0.05 | Max. 0.5 |

| Bonding Time with Vicat Tool: | |||||

| - Initial Bonding Time | Min | Minutes | 45 | 145 | ±30 |

| - Final Bonding Time | Min | Minutes | 420 | 260 | ±30 |

| - Air Content in Mortar | Min | % | - | 8 | ±3 |

| Compressive Strength Value Range: | |||||

| - 1 Day | Min | Kg/cm2 (Mpa) | 90 | 130 | ±10 |

| - 3 Days | Min | Kg/cm2 (Mpa) | 200 | 250 | ±20 |

| - 7 Days | Min | Kg/cm2 (Mpa) | - | 300 | ±20 |

| - 28 Day | Max | Kg/cm2 (Mpa) | - | 380 | ±20 |

| - Expansion of mortar bar 14 days | Max | % | Max 0.020 | 0.003 | Max. 0.020 |

Purwosari Flyover, Surakarta - Central Java

Sabo Dam Merapi, Magelang - Central Java

Salatiga Toll Road, Salatiga - Central Java

Thamrin Nine Tower, Jakarta.